- November 5, 2023

- Posted by: admin_marine

- Category: Global News

INTRODUCTION

Reference to marine industry reports indicates that Engine Room (ER) fires represent just over 60% of all shipboard fires. Further, that fuel oil spray leaks onto hot ER surfaces (e.g., turbocharger uptakes) continues to be the most common cause of all ER fires. Many of these ER fuel spray fires can be extinguished using fixed fire-fighting CO2 or water spray systems. Others become uncontrollable – often due to fire system failures or crew error – with resulting vessel total loss, oil pollution and crew injury or fatality claims. This Risk Bulletin seeks to raise Member awareness of ER fuel spray leaks onto hot surface risks and provide practical loss prevention recommendations.

BACKGROUND

Reports of the type of ER fires referred to above are available from numerous sources including the USCG, EMSA, the UK’s MCA and CEFOR (The Nordic Association of Marine Insurers. The problem appears to be that although ship casualty figures (inclusive of shipboard fires) appear to be showing a general downward trend, this is not the case for ER fires.

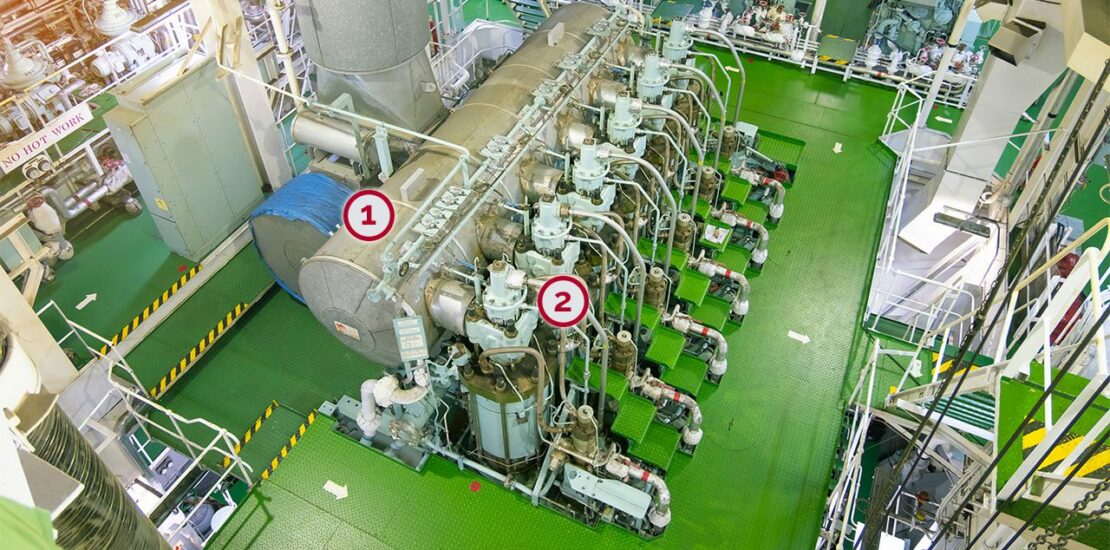

The reports also indicate that almost two-thirds of these engine room fires occurred within the main and auxiliary engines and their associated components. Most of these incidents appear to have been caused by a failure in a flammable oil piping system, most often in the low-pressure fuel oil piping, creating a spray of oil onto an unprotected hot surface. A case-study example of such an incident is summarised as below.

CASE STUDY/LESSONS LEARNED

A copper pipe fractured which was part of the fuel pressure gauge system for a diesel generator. Diesel fuel then sprayed out onto the unprotected and 400º C. surface of an adjacent exhaust turbo charger casing. The fuel ignited causing extensive damage in the engine room. Fortunately, the fire was extinguished, and no one was injured. However, the very costly repairs required 40 days of vessel downtime to complete.

Investigation showed that the copper pipe which fractured had been fitted during an unrecorded repair and it did not meet the original specification requiring a steel pipe. Further, the original fuel pipe spray shield had been removed during maintenance and had not been reinstalled. It was also clear that the inadequately insulated surface of the turbo charger exhaust casing was well in excess of the SOLAS regulatory maximum of 220º C.

The underlying cause of this incident can be attributed to a serious failure of regulatory compliance by both the vessel’s engine room crew and ship managers. The relevant regulations are as noted below.

REGULATORY REQUIREMENTS

The IMO’s SOLAS Convention, as amended, provides comprehensive regulation for fire safety on board ships. In force from July 2003, Chapter II-2/Reg.4, Probability of Ignition, provides detailed measures to reduce the risk of oil leaks igniting in engine rooms. Thus, for all ships regulated by SOLAS, the relevant requirements may be briefly summarised as follows:

- Jacketed (double) pipes must be fitted to all high pressure fuel oil delivery/injection piping;

- Insulation of all high temperature surfaces (exceeding 220º C) and at risk of flammable oil impingement after a failure of an oil line is mandatory; and

- Spray shields must be fitted to flammable oil lines (fuel, lubrication and hydraulic oil) located immediately above or near potential ignition sources.

The aforesaid SOLAS Chapter II regulations have since been supplemented and updated by several IMO MSC resolutions. All this information has been usefully consolidated into 35 pages, complete with colour diagrams, by MSC.1/1321, Guidelines for Measures to Prevent Fire in Engine-Rooms and Cargo Pump Rooms.

NOTE: The IMO Guidelines do not supersede the SOLAS regulations but – as explained – serve only to provide a uniform and harmonized information guide to naval architects, ship builders, flag states, class, ship owners and, very importantly, engine room crew.

The MSC.1/1321 Guidelines refer to both ‘high pressure fuel oil systems’ which operate at pressures of 10.0 N/mm2 or above; and ‘low pressure fuel oil systems’ which operate at pressures between 0.18 N/mm2 and 10.0 N/mm2. The advice provided is as follows:

“If oil fuel lines fail, spray patterns may occur. These spray patterns depend on the pressure of the system and the failure condition… Droplet diameter is one of the factors and is dependent on fluid pressure and size of failure. Generally, the smaller the droplet size the greater the fire risk when the fuel system is under high pressure and a small orifice exists, as this results in the atomization of the fuel oil. Therefore, a small crack in a high-pressure oil fuel pipe may lead to a most dangerous situation.”

This is critical information but there appears to be an on-going industry concern that not enough attention is being paid by the IMO’s Marine Safety Committee (MSC) to the similar dangers which – as described in the case study above – can also arise when failures occur in low pressure fuel oil systems. Members should therefore ensure that their fuel oil leak risk management systems extend to include all fuel oil piping and systems in the engine room.

REGULATORY COMPLIANCE

Members whose vessels are regulated by SOLAS (i.e., all ships over 500 GT engaged in international trade) should ensure that the texts of both the latest 2020 Consolidated Edition of SOLAS and the MSC.1/1321 Guidelines are readily accessible to all their vessels, DPAs and ship managers.

Members whose vessels are engaged in domestic trade only will likely be regulated by similar national flag state NCVS regulations. They should ensure that the text of these regulations and the MSC/1.1321 Guidelines are readily accessible to their vessels, DPAs and ship managers. If there is any uncertainty, then Members should confer directly with their vessel flag state authority or its appointed Recognised Organisation (RO).

All Members should also ensure that the relevant SOLAS or similar NCVS regulations and the MSC.1/1321 Guidelines are specifically incorporated into their ISM Code or similar NCVS SMS manuals and procedures. Further, that full implementation and regulatory compliance is verified during both internal and external audit processes.

CONCLUSION AND TAKEAWAY

ER fuel system fires on board all types of ships – from smaller fishing vessels and tugs through to large bulk carriers, containerships and tankers – are evidently the principal cause of all shipboard fires. The outcome of ER fires can be catastrophic at worst and, at best, will likely be dangerous and, afterwards, very expensive to repair. The most effective defence is of course to prevent such incidents from occurring.

MM’s recommendations to Members are as follows:

- On board SOLAS regulated vessels, ensure full compliance with both SOLAS Chapter II-2/Reg. 4 and MSC.1/1321 as well as the incorporation of these regulations and associated guidance into ISM Code/SMS procedures and related audit processes. On board domestic trade/Non-Convention vessels, ensure full compliance with equivalent or similar national flag state NCVS regulation.

- As an essential part of the compliance process, encourage ship managers and shipboard crew to:

- Routinely check, identify and rectify any possible source of fuel system leakages inclusive of the use of non-original design parts, loose fittings/couplings, missing bolts, worn or damaged hot area insulation and missing spray shields.

- Carefully note any deficiencies as SMS ‘non-conformities’ and ensure urgent rectification, inclusive of an SMS recorded ‘close out’.

- As part of SOLAS or NCVS required emergency drills, ensure that ER fire drills include ER evacuation, ventilation shut down and door closure, the operation of the emergency fuel shut off system and the fixed firefighting system. All such drills should be recorded in the Deck and ER logbooks. Any equipment or operational SMS deficiencies should be noted as ‘non-conformities’ and rectified urgently, inclusive of an SMS recorded ‘close out’.

NOTE: ER fires often become major casualties because of emergency fuel shut off system, ventilation shut down or fixed firefighting system failures. It is therefore essential for these systems to be physically tested on a regular and always carefully supervised basis (i.e., attendance of a manufacturer’s representative may be required). - Finally, and bearing in mind the high cost of ER fire claims exposure, repairs and vessel downtime, Members may wish to consider the utilisation of thermography ‘hot spot’ detection and/or fuel system oil mist detection technology. The use of such ER fire risk detection systems is not yet a regulatory requirement, but they are currently in routine use by cruise ship and container vessel owners who are exposed to high levels of both asset and downtime risk.

NOTE: Thermography is also being utilised to detect potential mechanical failure for maintenance planning and prioritisation purposes.

Source : mutual-marine.com